Products

An eco-sustainable solution

For better safety on the roads

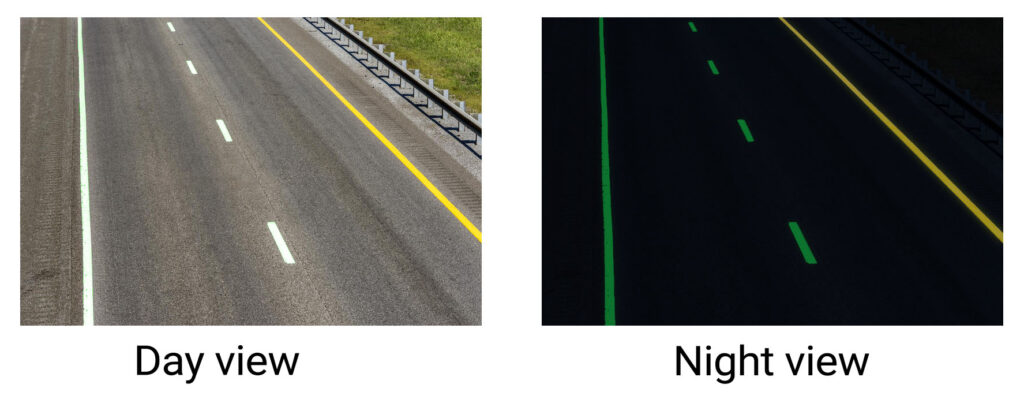

Poor visibility at night is one of the biggest challenges on roads, and it can lead to hazardous situations. However, adding long-afterglow light-emitting phosphorescent materials to traffic white paint can be a solution to this problem.

Afterglow luminous powders can absorb sunlight or ambient light throughout the day and release it as colored light during the night, which makes them an advanced technology compared to other solutions.

Benefits of EverBrightGreen®

Application and Considerations

To achieve the best visibility at night, a paint-to-material ratio of 1:0.3 is recommended, optimizing the light output. Methyl methacrylate-based road paint with EverBrightGreen® materials is an ideal choice for this technology. It provides the necessary protection, longevity, and adhesion to road surfaces.

Visibility evaluation findings

- Under normal weather conditions, brightness

was increased by 4 mcd/m2. - Under foggy weather, brightness was

increased by 4 mcd/m2. - Under rainfall conditions (30 mm/h), brightness

increased over 13 mcd/m2. - In the absence of a streetlight and a headlight,

the white line was completely invisible while

the new road marking was still visible with a

brightness of about 0.6 mcd/m2. - The proposed new road markings meet the

minimum requirements of the human eye

detection of 0.32 mcd/m2 under adverse weather

conditions.

Durability and sliding resistance

- Wear resistance depends on particle size and sample concentration.

- The larger the particle size, the better the durability.

- The optimal particle size is 50–250 microns.

- Sample loading concentration in the range of 15–50%

Environmental impact

- There is no need to use street lighting, especially in rural areas, at least for a few hours, and this reduces CO2 emissions.

- Compared to the existing white paint, the EverBrightGreen® can absorb more light from the sun, reduce the ambient temperature, and thereby fight the urban heat island effect.

- Concentrations of the elements inside the compound meet the soil and water clean target levels of the United States Environmental Protection Agency (EPA).

- Retroreflective glass beads contain high concentrations of heavy metals such as lead, cadmium, arsenic, etc., and under various environmental conditions, they can release heavy metals into the environment.

- By using glass beads, concentrations of arsenic exceeded the country limits of 3 g/L, lead exceeded 65 g/L, and antimony exceeded 78 g/L.

- Glass beads are used at a concentration of 72%, which is far higher than the 20–40% concentration range of the present technology.